How Do You Mitigate Large Scale Distribution Risk For 3 Million Constituents?

https://www.crs.org/our-work-overseas/ict4d

Food distribution is a huge part of foreign aid in times of food insecurity. For Ethiopia, around 1.5 million acute food insecure households have received food aid, worth up to 125 million USD this year.

In 2016, during the peak of the emergency response to the drought, almost 3 million constituents received a portion of this food aid. Such a large-scale distribution reveals wondrous efforts, but with any distribution project, there lies a risk that the goods are not going to the desired recipient.

Some locations and situations present a greater risk than others. The food distribution point may be too far for families, political instability may create an unsafe environment for distributing, unexpected weather may cause destruction to a storage warehouse, and food can be intercepted by other actors. International development has often not been able to understand what complexities increase or reduce risk for distributing.

This information is essential in prioritizing follow up to reduce loss. Humanitarian actors cannot be everywhere at once and near-real time risk information is essential to prioritize where we need to be to reduce food loss.

Ethiopia’s Risk Management Model      Â

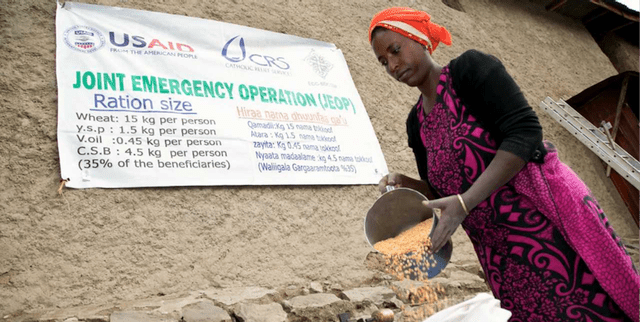

For Catholic Relief Services’ (CRS), it all comes down to making the complex actionable and easy to understand. The Joint Emergency Operation (JEOP) has been ongoing in Ethiopia for over ten years. This massive program can account for up to one third of emergency-affected Ethiopia.

To reduce and track loss they have created a risk management system to prioritize areas most in need. This risk management model focuses on the “last mile†of distribution, or, the point of primary distribution to the constituent. Such a basic operation requires complex support. Using an ICT solution, CRS has created a risk model that assesses certain factors for each food distribution point.

The program digitally collects and ranks various factors that contribute to a risk index. This index appears on an online platform, which instantly alerts program staff to where they need to respond. A higher risk level allows CRS to properly reallocate resources and staff to those locations. Since the risk management approach was introduced in 2016, only 0.0024% of food was unaccounted for, a near impossible achievement for distribution of such immense size.

How Does It Work?

In order for a distribution project of such size to function efficiently, the risk measurement system uses four techniques.

- Labor, otherwise known as key human resources, ranging from data collectors to risk and compliance monitors.

- Assessment tools, or identifiers are used to categorize each food distribution point according to: physical warehouse condition, records management, internal partner monitoring, distributions, end use checks, market and mills, complaints, and incidents.

- Risk models identify ten specific risk drivers such as fiscal liability or environmental conditions to compile a calculation for each food distribution point.

- Risk management dashboard displays the risk findings in visual reports and allows for users to follow up, verify reports, and share incident reports.

The risk management system uses a series of online software to calculate and report risk levels for each distribution district:

- Monitoring Level: Data is collected electronically from the field from randomized and intentional checks.

- Compliance Level: Data goes into a staging warehouse and risk management application where all the different fields are calculated to assign risk

- Management Level: Data and risk is displayed on a dashboard to help make project decision.

Field workers use tablets installed with digital data collection software where the data is then cleansed in a web-based management application. This management application manages all reports sent in from the field, verifying data, tracking incidents, and providing follow up action.

The cleansed data is stored in an online database and extracted into an interactive dashboard to display figures through graphics and consolidated reports that are easy to understand. These reports allow for important findings in the distribution process and configures the “last mile†to function with minimal loss.

For each food distribution point, workers in the field must collect a number of factors. These factors are equated with a numerical value that comprises a risk calculation using algorithms. The calculations are compared among woredas (or districts) to rank situations posing higher risk. The below graphic list CRS’s indicators for risk and how these indicators calculate into the different risk levels.

Risk Management Accomplishments

After the introduction of the risk management system, JEOP has seen a number of improvements. Open findings, or discoveries that negatively impact or pose risk for distribution efforts, have been decreasing since the risk model has been introduced.

Because of the open data and dashboard reports, monitoring of the distribution process has become very transparent. This transparency provides incentives for everyone involved such as warehouse operators to be efficient and properly document commodity data.

One of the biggest findings since the risk model implementation was weakness in warehouse management. Due to the open data and visual evidence from the dashboard, JEOP was able to secure an additional one million USD for solving the warehouse mismanagement. Weaknesses in distribution compliance standards were also found in the risk model.

This led to staffing adjustments such as more distributors and risk monitors to prevent further compliance findings. JEOP also hired compliance officers to address this weakness. Due to these adjustments, open findings have decreased by 54% since the inception of this checks and records management.

If ICT can have such a positive impact on large scale distribution, this risk model should be implemented for other projects. While the JEOP has been a success over the last ten years, the risk model has improved it even more. Food security in Ethiopia will benefit from the extra step CRS has taken to improve efficiency for acute food insecure households.

Because there are so many development distribution projects and loss occurs with every program, risk management should become a standard. CRS is looking to see how we can incorporate this approach in other large-scale distribution programs.

JEOP’s risk management system is an incredible innovation that has taken complex data and algorithms and made it actionable with direct and immediate benefit to the recipients. With such success of minimizing loss, USAID has taken an interest in this approach. The program looks to standardize the process for replication so that risk management and reduction may be available for any program, no matter how large, small, or remote.

By Madison Lawson, ICT4D Training and Communications Assistant, Catholic Relief Services